Corrosion!

- February 27, 2021

- Suzuki

- Posted by cx79p

- Leave your thoughts

Probably the number one reason to buy from Japan!

There are many reasons to buy an imported car from Japan.

The average mileage is extraordinarily, and genuinely low.

The way the Japanese look after their vehicles is verging on obsessive.

Their equivalent of the MOT, the Shaken is so rigorous, the vehicles are in superb condition.

But the number one reason is that they don’t salt their roads.

Technically this isn’t strictly true, as in some regions, in the north, a limited amount of salt is used , but in general salt doesn’t have widespread use.

Basically cars are made of metal, predominately steel, and steel contains the element Iron, or Fe.

Even car’s like Land Rovers, which are famously made from aluminium ‘so they don’t rust’ are built on a frame and chassis of steel. At it’s most basic level, iron (within the steel) oxidises, in the form of rust, and salt water greatly accelerates this.

I personally would prefer the UK to get tougher on the laws surrounding tyres, and limit their use of salt.

If we were encouraged to use tyres with greater tread depth, and also, winter tyres for six months of the year, the outlay would be far outweighed by the longevity and safety of the vehicles we drive. Another plus would be the saving on gritting the roads every year.

One of the most underselaled vehicles in the UK right now are Land Rover Defenders. As their value rises, the need to protect them increases, and their construction means they are notoriously very prone to rot.

The very thing which gives Land Rover and the Suzuki Jimny their outstanding offroad ability is their Achilles heel.

That is they are both built on a ladder frame chassis.

Above is the chassis of the new Jimny. It helps to give it an outstanding offroad performance, but is far more susceptible to rust than a monocoque. It has many drainage holes, which can collect water, and more damaging salt water.

This is why we advocate a full program of underbody anti corrosion.

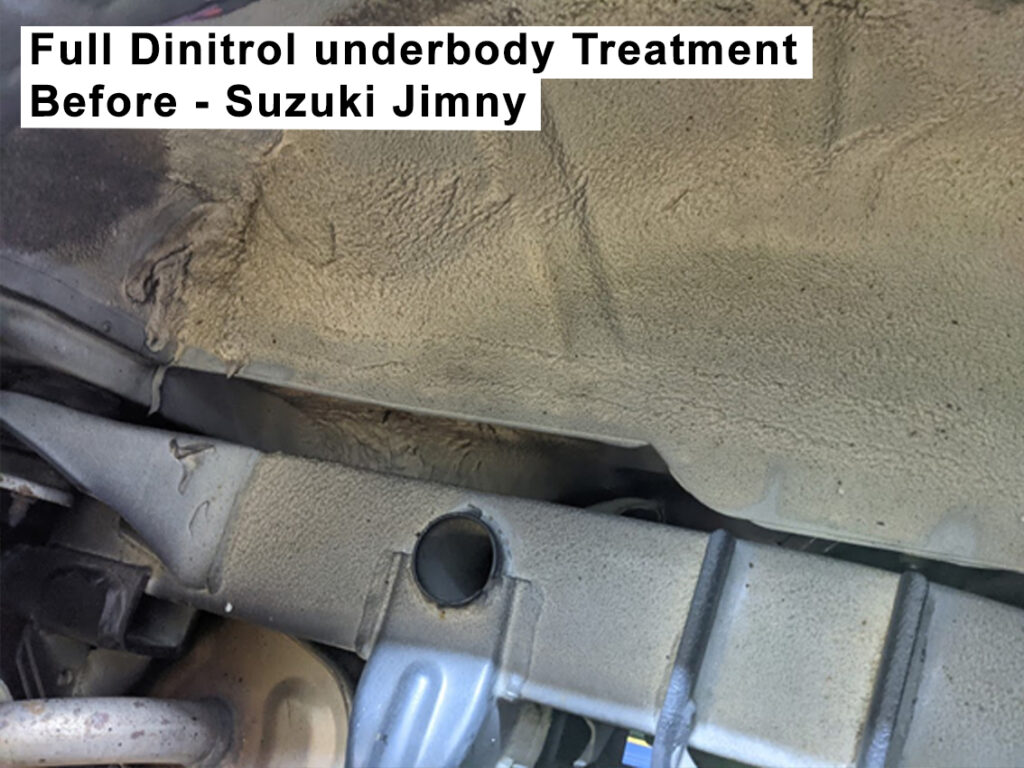

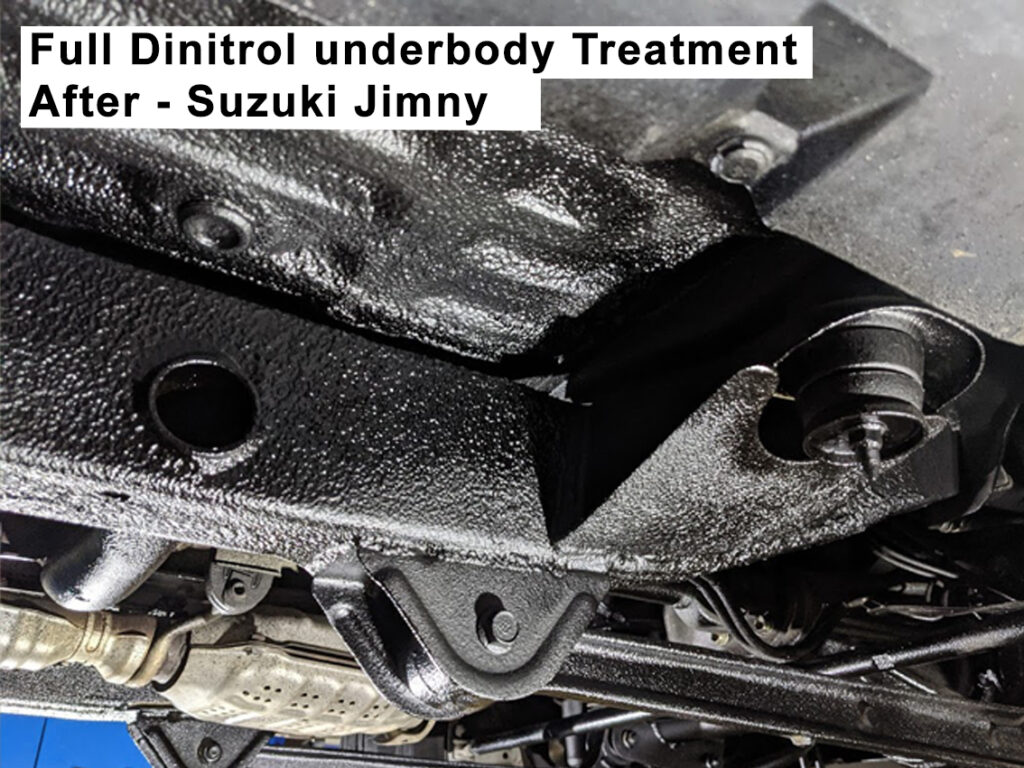

Below are some images of a UK vehicle, a 4×4, and one of our fresh imports before and after a full Dinitrol underbody treatment.

The corroded photos are from a UK vehicle which came in for an MOT with us. It required welding on the chassis. When a vehicle needs welding on the chassis, it is because the strength and integrity is compromised. One of the tests used is to see if a screw driver, or sometimes a finger, can be pushed through the metal. When it gets to this stage, although treatable, it is really difficult to hold back the tide year in and year out.

If you look carefully at the nuts on the corroded chassis, they are a mechanics worse nightmare. They are often completely corroded onto the thread, and have the potential to snap at any minute. Couple this with the perished rubbers, of which this type of vehicle has many, and any work needed would be a possible nightmare.

Whereas, if you look at the nuts on the fresh import, it is like a new car. Still having driven around for the last 10+ years, the difference is like night and day.

We can not stress enough the importance of underbody treatment.